Granulators are an important in fertilizer production lines, transforming loose powdery raw materials into uniform granules through processes such as mixing, pressing, and shaping. This conversion not only enhances the quality but also significantly improves the stability of the fertilizer. As a specialized manufacturer of fertilizer machinery, we provide a wide range of granulators, each designed to produce high-quality granules tailored to meet the specific needs of various fertilizer types.

-

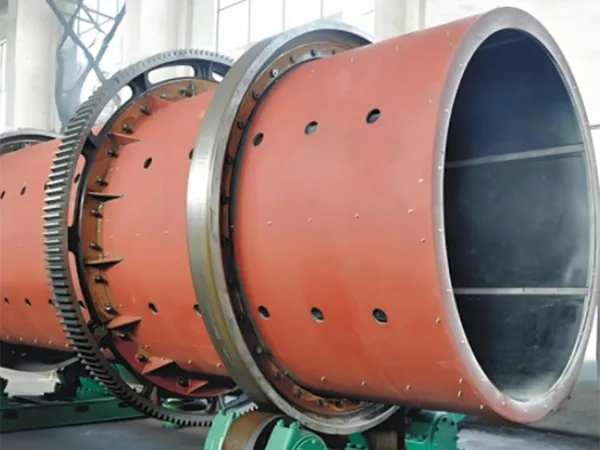

- Rotary Drum Granulator In fertilizer production, rotary drum granulators are necessary to turning powdery materials into solid, uniform granules. This granulating equipment is commonly used for making compound fertilizers with different nutrient levels, from low to high concentrations.

- The inside of the drum is lined with special rubber plates that help with self-cleaning and prevent corrosion. For more durability, options like engineering plastic or stainless steel can be used as linings.

- The gear rings and support rollers are made from cast steel, which increases wear resistance and ensures the drum lasts longer, even during heavy use.

-

- Rotary Drum Spray Dryer Granulator Efficient granulation and drying are necessary to producing consistent fertilizer granules; our rotary drum spray dryer granulator is designed to combine these processes.

- Tooth-shaped lifting flights inside the drum help form a uniform material curtain. The slurry is sprayed through pneumatic nozzles, evenly coating fine particles within the drum. As the material moves through the drum, heated air from the furnace ensures efficient drying, creating solid and uniform granules.

- Larger particles are crushed and returned to the beginning of the process for re-granulation, while fine particles are recycled back through an internal system, optimizing the efficiency of the overall granulation and drying operation.

-

- Roller Compactor Dry Granulator Granulation using roller compaction is an efficient method for transforming powder materials into solid granules. The roller compactor dry granulator achieves this by compressing powders between rollers with semi-circular grooves, producing stable granules without the need for steam or binding agents.

- The roller compactor dry granulator is engineered for large-scale fertilizer production, thanks to its ability to run multiple machines in parallel, ensuring a continuous process. This setup helps maintain high production rates while minimizing downtime.

- Granulation with this equipment guarantees uniform size and shape of the granules, which translates to more efficient field application and better nutrient uptake by crops.

-

- Disc Granulator The disc granulator is a machine designed to turn powdery materials into spherical granules through a combination of water, solution, or even steam, added as liquid phases.

- The inner lining of the disc is made from high-strength fiberglass, providing excellent corrosion resistance. For more durability, stainless steel linings are also available.

- The base is designed to be thick, heavy, and sturdy, allowing stable operation without the need for anchor bolts.