Potassium Sulfate Fertilizer Production Line

Fertilizer production solution with Mannheim furnace for potassium sulfate fertilizers

Potassium Sulfate Fertilizer Production Line

Fertilizer production solution with Mannheim furnace for potassium sulfate fertilizers

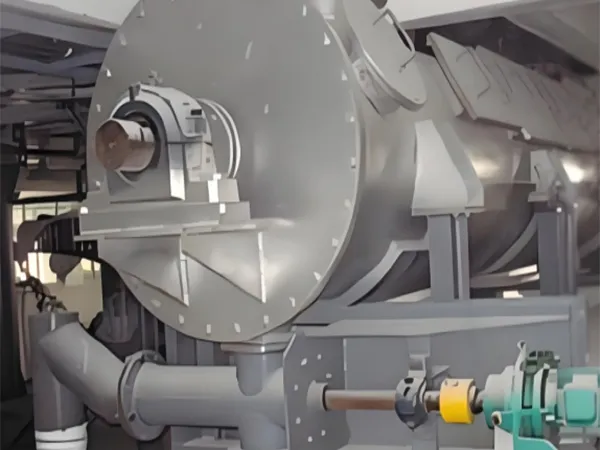

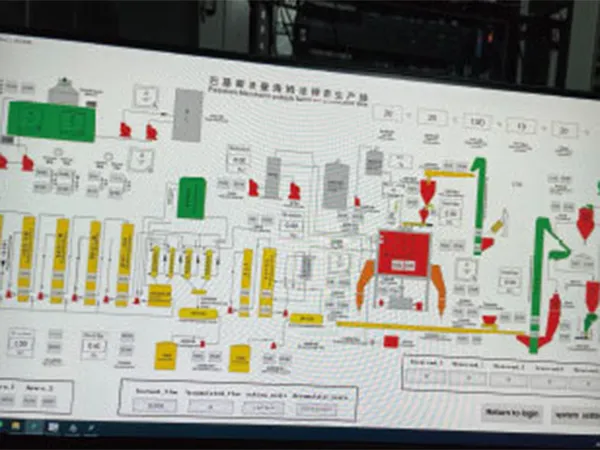

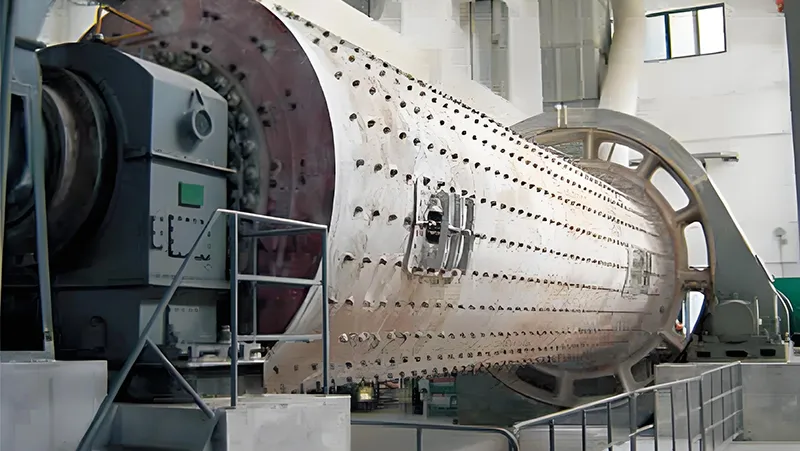

Potassium sulfate fertilizer production utilizes the Mannheim process, where potassium chloride and concentrated sulfuric acid react at high temperatures. Inside the double layer Mannheim furnace, with rakes to move the mixture, temperatures reach 600-700°C. The molten mixture is slowly moved by rotating rakes, ensuring efficient contact between the components. As the reaction progresses, potassium sulfate forms and is discharged from the sides. After cooling, the final potassium sulfate product is ready for further processing.

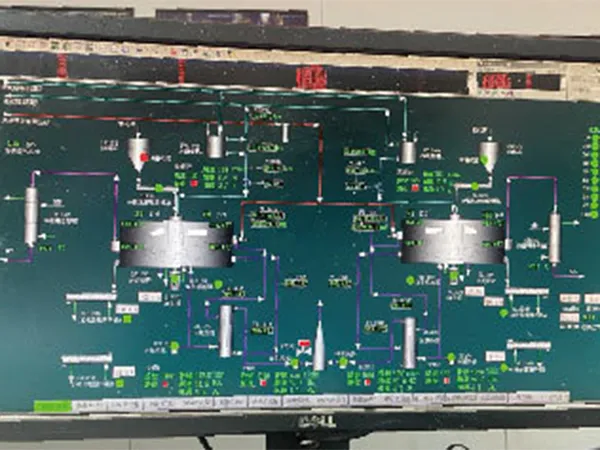

Our potassium sulfate fertilizer production lines support an annual output of 10,000 to 200,000 tons, featuring a comprehensive setup with storage tanks, the Mannheim furnace, conveyors, and packaging systems. The Mannheim furnace is designed to improve upon traditional German dry roasting methods, offering enhanced efficiency and reliability, even in corrosive high-temperature environments. Continuous feeding and improved handling of high-concentration acids have been successfully integrated into the system.