Compound Fertilizer Production Line

Fertilizer granulation solution for NPK compound fertilizers

Compound Fertilizer Production Line

Fertilizer granulation solution for NPK compound fertilizers

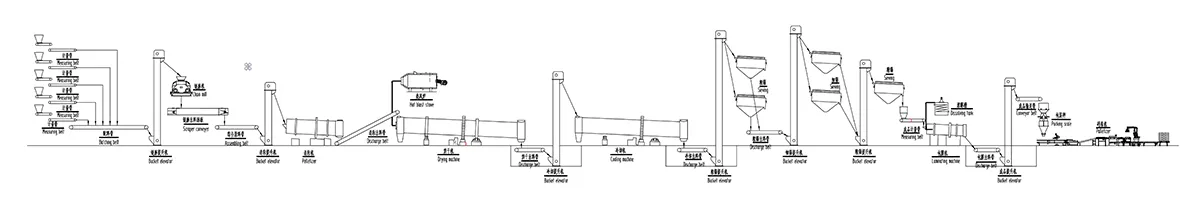

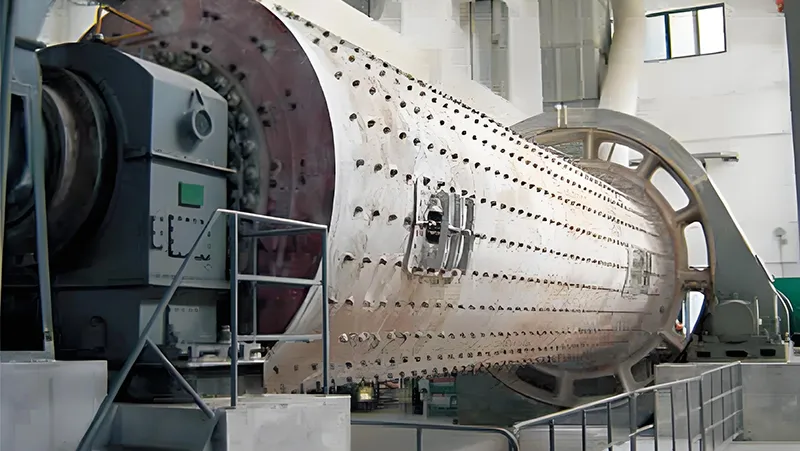

The wet granulation process is used for the production of NPK compound fertilizers. It starts with raw materials such as urea, ammonium nitrate, ammonium chloride, ammonium sulfate, phosphate (MAP, DAP), superphosphate, and potassium chloride (or potassium sulfate). These materials are crushed to a specific fineness and then undergo granulation in a rotary drum granulator (or disc granulator). During this process, the materials are moistened and heated to form granules. In some cases, small amounts of phosphoric acid and ammonia are added to the granulator to improve granulation conditions. The resulting granules are then dried, screened, and cooled to produce the final NPK compound fertilizer product.