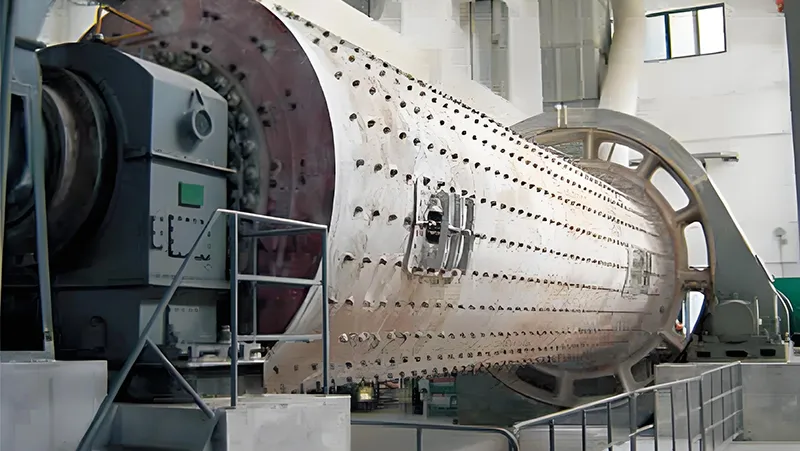

A customer in Vietnam initially required a fertilizer production line with a 150,000 tons annual capacity. Considering the region's high humidity and warm climate, which can cause materials to clump and reduce granulation efficiency, we adjusted the production line design. By improving the process flow and optimizing equipment selection, we extended the length of certain drum equipment and redesigned the discharge box. This allowed the production capacity to reach 200,000 tons per year, far exceeding the customer’s expectations. Throughout the entire project, our engineers were present on-site, providing hands-on guidance from civil engineering work to plant layout, as well as fertilizer equipment installation and commissioning.

Additionally, we offered a one-year free quality assurance service to ensure customer satisfaction.

The client requested a turnkey project for a production line capable of producing 100,000 tons of compound fertilizer annually. Due to time constraints, we coordinated the factory construction alongside the equipment installation.

Our team ensured that the equipment setup aligned with the workshop construction, making installation and crane operations more efficient.

Longguang Tech successfully completed a turnkey project for a 150,000 tons compound fertilizer production line within 6 months. After two months of negotiations, the client trusted our capabilities. Our technical team quickly developed a preliminary plan based on the client's requirements, followed by detailed discussions. Once the contract was signed, the equipment was delivered and installed within six months, followed by comprehensive training for the operators, ensuring smooth production.

This project initially involved a single dryer and cooler system, but after evaluating the local environmental conditions, we recommended using two dryers instead. The client followed our advice, resulting in optimal production efficiency.