Breaking down large raw materials into smaller, manageable particles is an important process in fertilizer production. Crushers are designed for this purpose, ensuring that raw materials are properly prepared for further processing. We offer a variety of crushers, depending on material type, our crushing equipment can be tailored to meet specific production needs. Whether working with hard or softer materials, the right crusher optimizes processing efficiency and ensures consistent results, making subsequent stages like granulation and drying more effective.

-

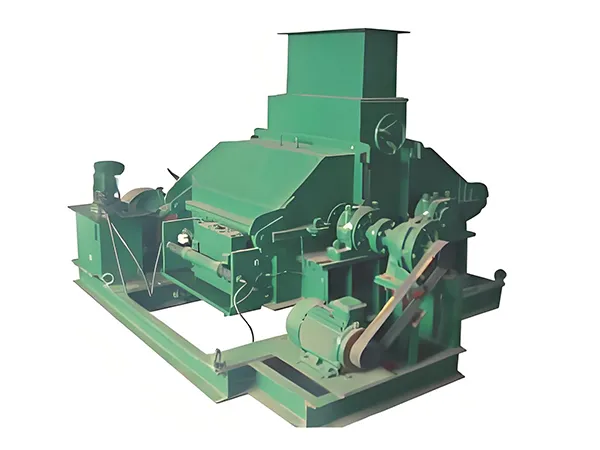

- Hammer Roller Crusher Granular fertilizers and other large raw materials require effective crushing to streamline production processes, and the hammer roller crusher is an ideal solution for that task. Its design allows it to break down materials such as ammonium phosphate, NPK fertilizers, and urea into smaller, uniform pieces, improving the efficiency of subsequent stages like granulation or mixing. Equipped with a hydraulic cleaning system and long-lasting wear components, it features reliable, continuous operation with minimal downtime. Besides processing fertilizers, the versatility of this crusher makes it suitable for industries such as light manufacturing, building materials, and metallurgy, offering consistent performance for diverse applications. Learn More

-

- Cage Mill Crusher Cage mill crushers are mainly designed for fine crushing processes and offers the added benefit of evenly mixing materials during the process. This type of crushing equipment is ideal for breaking down brittle materials and is especially effective in separating clumped powder. Thanks to its capacities, this crusher is suitable for crushing single-component fertilizers with moisture content below 6%, and it works exceptionally well on harder materials, providing efficient size reduction. Learn More

-

- Horizontal Chain Mill Crusher Developed to tackle the challenge of crushing fertilizers that absorb moisture, the horizontal chain mill offers a smooth and continuous crushing process. Its structure prevents material buildup on the inner walls, ensuring uninterrupted operation. With high efficiency, large production capacity, and simple maintenance, our horizontal chain mill crushers are ideal for processing blocky fertilizers and other medium-hard materials. Its user-friendly design also makes it a versatile tool for improving fertilizer production, overcoming issues that typically hinder crushing in other systems. Learn More

-

- Vertical Pan Mixer Achieving consistent blending is crucial for industries handling fertilizers, animal feeds, and other powdered materials. The vertical pan mixers we offer address this need as it is equipped with rotating blades attached to a central shaft. These blades gently lift the materials from the bottom and allow them to disperse evenly as they fall, ensuring a smooth and even mixture.

- The interior of the pan is lined with polypropylene or stainless-steel plates, making it resistant to corrosion and wear, while preventing material adhesion.

- This mixer is suitable for a wide range of materials, whether they are dry or wet granules or powders, offering flexibility for various applications.

-

- Urea Crusher Urea crushers use the combined forces of compression and shearing generated by two counter-rotating rollers to efficiently reduce the size of the urea particles. Commonly used in fertilizer production lines, this crusher ensures uniform particle size distribution, crucial for optimal fertilizer application. Additionally, it supports high-capacity operations and can be integrated into various production processes, making it an essential tool for improving product quality and production efficiency.

- The crusher and the rollers are made from 304 stainless steel, providing excellent corrosion resistance for reliable and long-lasting use.

- The adjustable particle size allows for fine-tuning, ensuring the output can be tailored to specific production requirements.

-

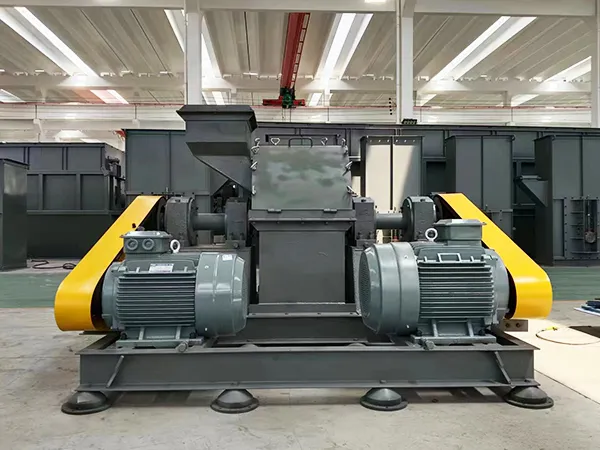

- Four-Shaft Crusher Breaking down compacted materials into smaller, manageable pieces can be a difficult task, especially in industries dealing with bulk fertilizers like ammonium chloride, potassium sulfate, or compound fertilizers. Four-shaft crushers are the solution to overcome this challenge as they are designed for this task. Its four rotating shafts, each equipped with specialized teeth, work by shredding clumped materials into smaller, manageable particles.

- The crusher and the rollers are made from 304 stainless steel, providing excellent corrosion resistance for reliable and long-lasting use.

- The adjustable particle size allows for fine-tuning, ensuring the output can be tailored to specific production requirements.

-

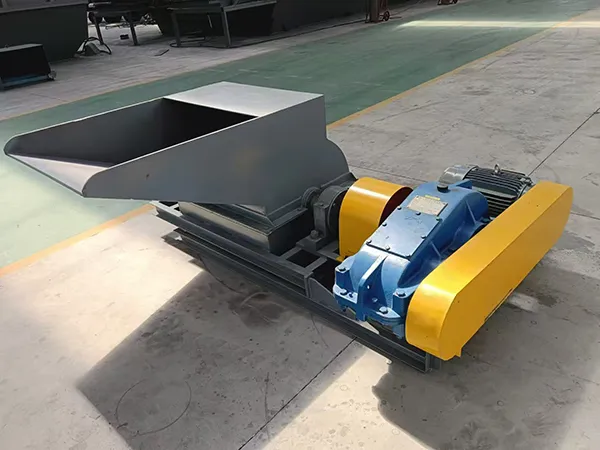

- Lump Breaker The single shaft lump breaker is commonly used in the fertilizer industry to handle materials such as ammonium chloride, potassium fertilizer, and ammonium carbonate. Over time, these materials tend to clump together when stored, forming large lumps. Before feeding the raw materials into the production line, this lump breaker performs a rough break, reducing large clumps, some as big as several centimeters, down to sizes below 3-4 cm.

- The tooth knives are made of high-strength, wear-resistant alloy steel, ensuring a long service life.

- Operates with high torque and low speed, which reduces dust production during material processing.

-

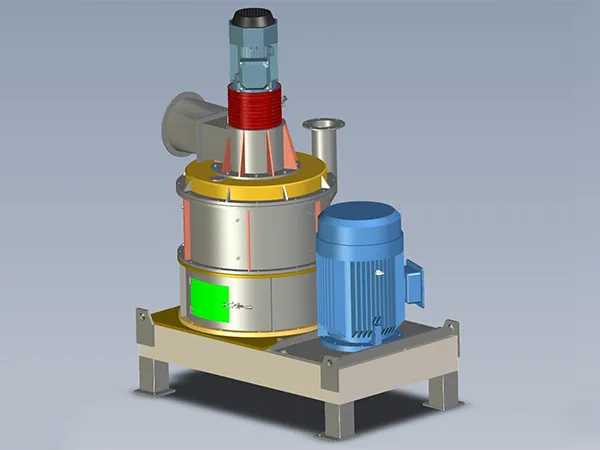

- Micro Powder Grinding Mill High-speed milling combined with precision grinding and micronization offers an efficient solution for producing fine powder products. The micro powder grinding mill integrates several systems, including feeding, grinding, classification, and an airflow system, ensuring an enhanced process from raw material input to finely milled output. With a combination of a rotating grinding plate, fixed gear teeth, and pressurized airflows, the mill repeatedly impacts, shears, and classifies the material until the desired powder consistency is achieved. Learn More

-

- Vertical Chain Crusher Vertical chain crushers are widely used in the fertilizer industry to crush medium-hard materials such as solid chunks of fertilizer. It features high-strength, wear-resistant alloy chain plates that rotate at synchronized speeds, ensuring efficient and uniform material breakdown. With a thoughtfully designed feed and discharge system, it helps maintain consistent material size while preventing blockages or adhesion inside the chain crushing machine, making it easier to clean. Its robust construction and reliability make it widely applicable not only in fertilizer production but also in industries such as chemical processing, construction, and mining, where consistent and efficient material processing is essential. Learn More

How to choose the right fertilizer production equipment for my plant?

Choosing the right equipment for your fertilizer production project starts with understanding your production needs. Here are a few key questions that help narrow down the best options:

- What type of raw materials are you working with?

- Do you aim to produce powdered or granular fertilizer? What specific characteristics should the final product have?

- What is the desired output capacity for your production line?

- What are the local environmental conditions, such as temperature and material moisture levels?

- What heat source will your drying equipment rely on?

Once we have this information, we can recommend the most suitable fertilizer processing equipment and production line for your needs.