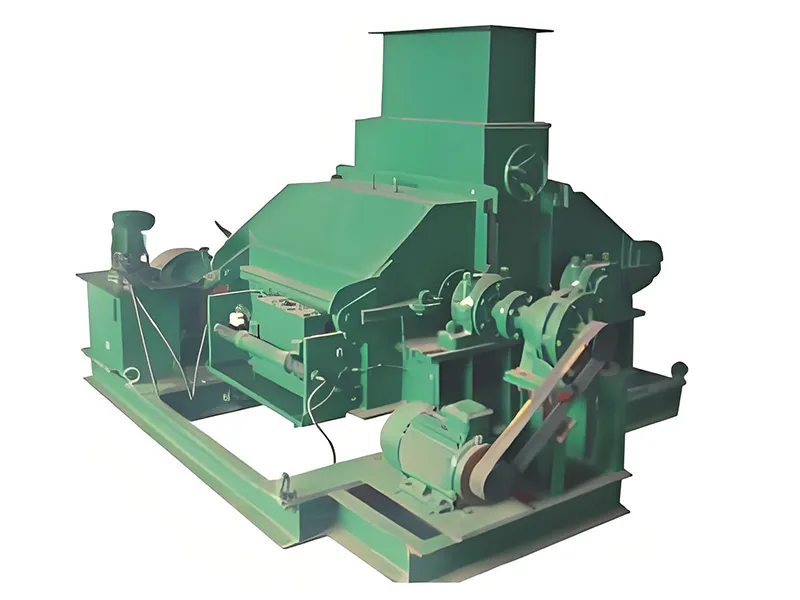

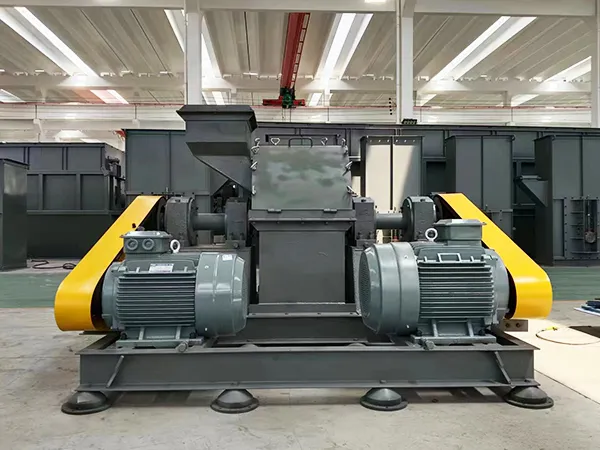

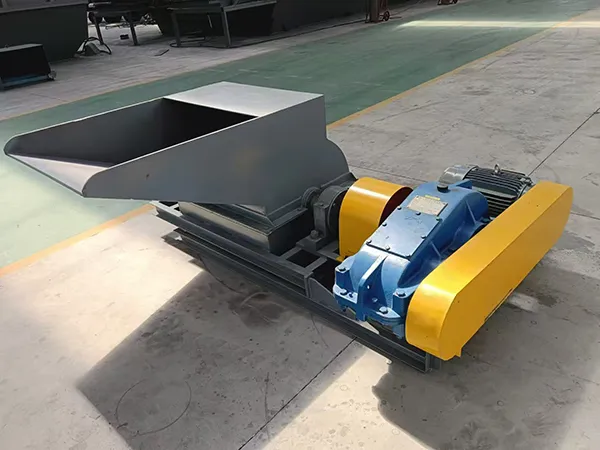

Hammer Roller Crusher

Fertilizer crushing machine for the size reduction of compound fertilizers

Hammer Roller Crusher

Fertilizer crushing machine for the size reduction of compound fertilizers

Granular fertilizers and other large raw materials require effective crushing to streamline production processes, and the hammer roller crusher is an ideal solution for that task. Its design allows it to break down materials such as ammonium phosphate, NPK fertilizers, and urea into smaller, uniform pieces, improving the efficiency of subsequent stages like granulation or mixing. Equipped with a hydraulic cleaning system and long-lasting wear components, it features reliable, continuous operation with minimal downtime. Besides processing fertilizers, the versatility of this crusher makes it suitable for industries such as light manufacturing, building materials, and metallurgy, offering consistent performance for diverse applications.

| Model | |||

| Production capacity | ≤25t/h | ≤40t/h | |

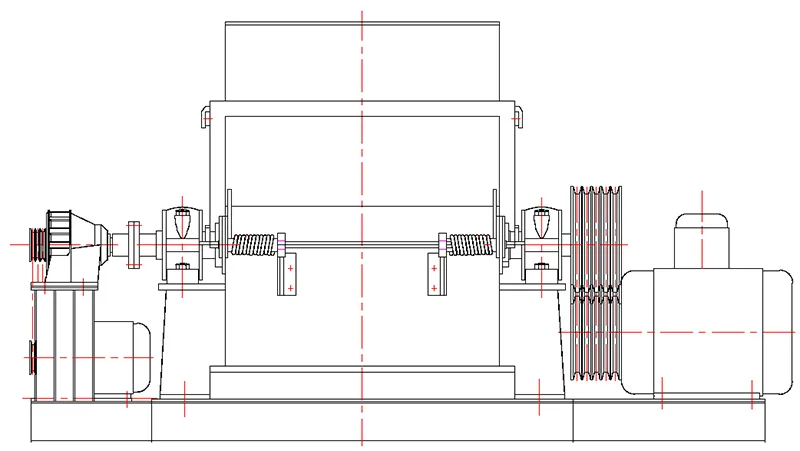

| Motor power | Toothed roll (with hammers) | 45kW | 55kW |

| Smooth roll | 5.5kW | 5.5kW | |

| Hydraulic pump | 0.75kW | 0.75kW | |

| Feeding size | ≤100mm | ≤100mm | |

| Final size | 1mm, 2mm, 4mm (with the percentage of 70-90%) | 1mm, 2mm, 4mm (with the percentage of 70-90%) | |

| Moisture content of feed material | < 5% | < 5% | |

| Machine weight | 4500kg | 6000kg | |

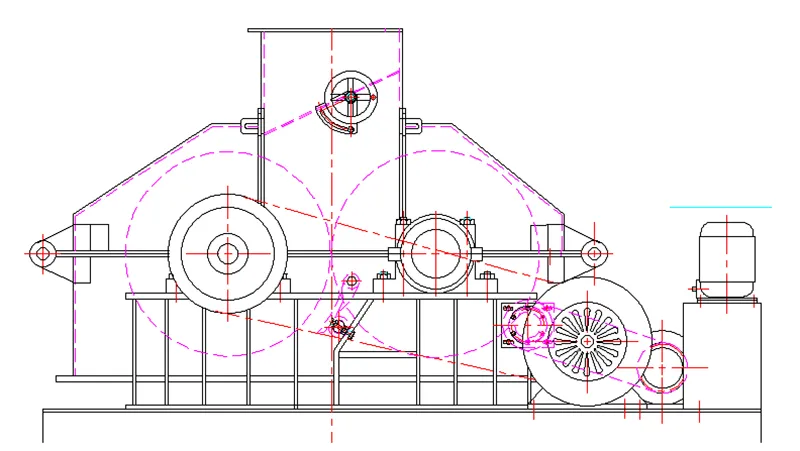

Hammer roller crushers operate using two horizontal shafts,one equipped with heavy hammers and the other with a roller. As materials are fed into the crusher, the hammers that are rapidly spinning break them down before the slower-moving roller further processes them. The resulting crushed material is discharged from the bottom for further production steps.

How to choose the right fertilizer production equipment for my plant?

Choosing the right equipment for your fertilizer production project starts with understanding your production needs. Here are a few key questions that help narrow down the best options:

- What type of raw materials are you working with?

- Do you aim to produce powdered or granular fertilizer? What specific characteristics should the final product have?

- What is the desired output capacity for your production line?

- What are the local environmental conditions, such as temperature and material moisture levels?

- What heat source will your drying equipment rely on?

Once we have this information, we can recommend the most suitable fertilizer processing equipment and production line for your needs.