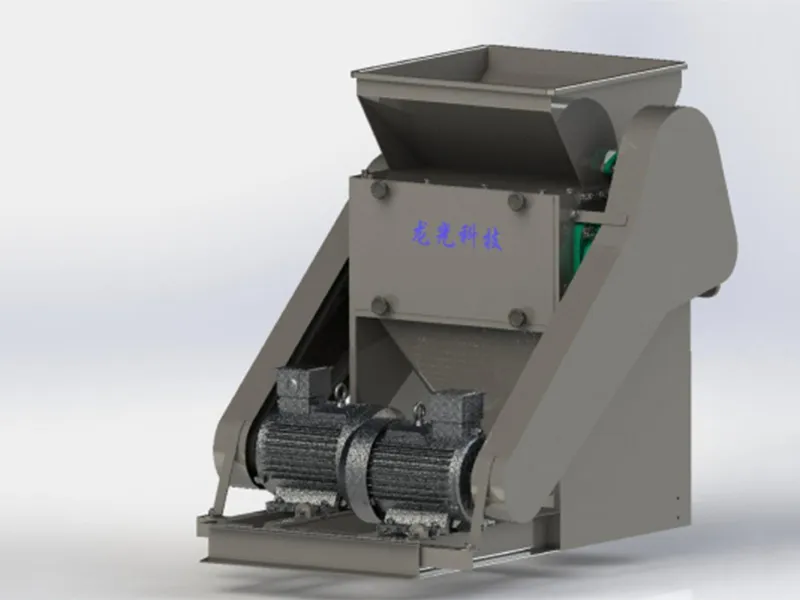

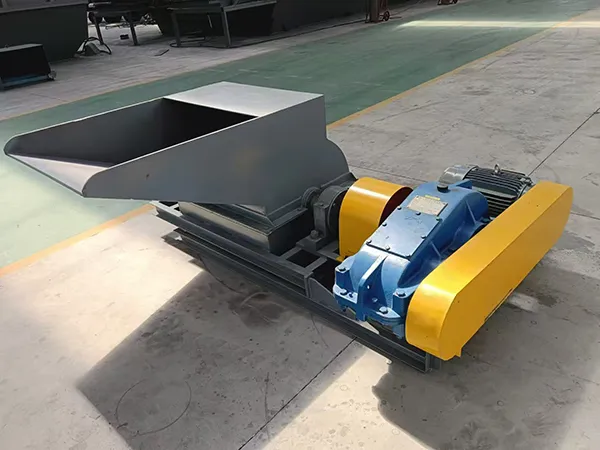

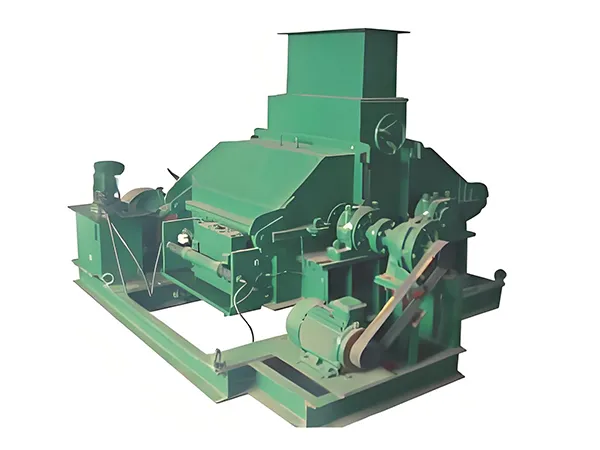

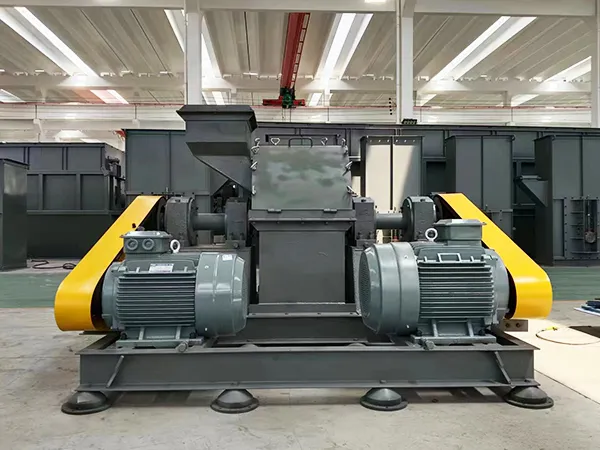

Urea Crusher

Double roll crusher for crushing urea particles into fine powders

Urea Crusher

Double roll crusher for crushing urea particles into fine powders

Urea crushers use the combined forces of compression and shearing generated by two counter-rotating rollers to efficiently reduce the size of the urea particles. Commonly used in fertilizer production lines, this crusher ensures uniform particle size distribution, crucial for optimal fertilizer application. Additionally, it supports high-capacity operations and can be integrated into various production processes, making it an essential tool for improving product quality and production efficiency. This crushing equipment is especially useful in handling urea-based fertilizers, where consistent particle size is important to enhancing performance.

| Model | |||

| Production capacity (t/h) | 2-3 | 3-5 | 5-8 |

| Feeding size (mm) | ≤5 | ≤5 | ≤5 |

| Final size (mm) | 0.2-0.5 (some are less than 0.2) | ≤0.2-0.5 (some are less than 0.2) | ≤0.2-0.5 (some are less than 0.2) |

| Rev. (r/min) | 800-1000 | 800-1000 | 800-1000 |

| Motor power (kW) | 5.5*2 | 7.5*2 | 11*2 |

- The crusher and the rollers are made from 304 stainless steel, providing excellent corrosion resistance for reliable and long-lasting use.

- The adjustable particle size allows for fine-tuning, ensuring the output can be tailored to specific production requirements.

- With independent roller drive systems, the urea crusher ensures smooth and stable performance, thanks to the well-designed roller speed and fine-slanted gear surfaces.

- This crushing system is designed to be easy to operate, requiring minimal maintenance with no easily worn parts or dust emissions, eliminating the need for additional dust collection systems.

- A safety grille at the feed inlet enhances operational safety by preventing large debris or foreign materials from entering the crusher during operation.

How to choose the right fertilizer production equipment for my plant?

Choosing the right equipment for your fertilizer production project starts with understanding your production needs. Here are a few key questions that help narrow down the best options:

- What type of raw materials are you working with?

- Do you aim to produce powdered or granular fertilizer? What specific characteristics should the final product have?

- What is the desired output capacity for your production line?

- What are the local environmental conditions, such as temperature and material moisture levels?

- What heat source will your drying equipment rely on?

Once we have this information, we can recommend the most suitable fertilizer processing equipment and production line for your needs.