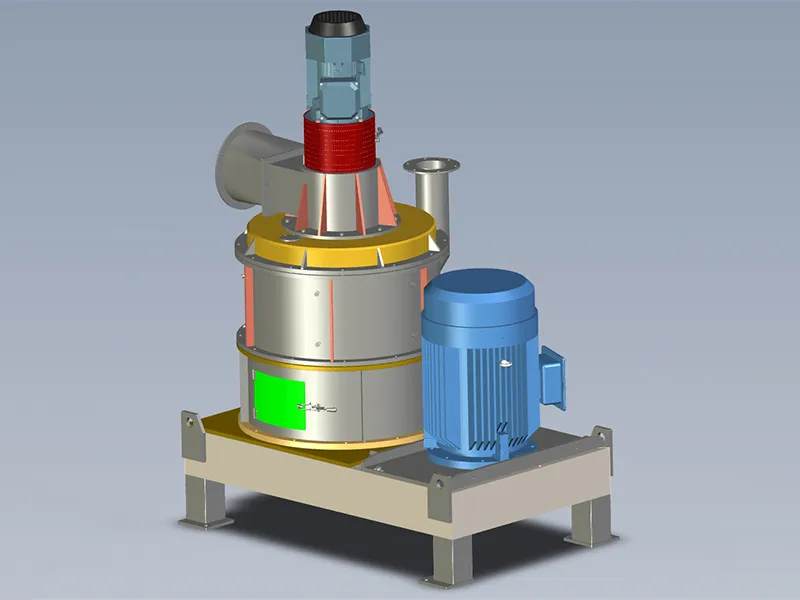

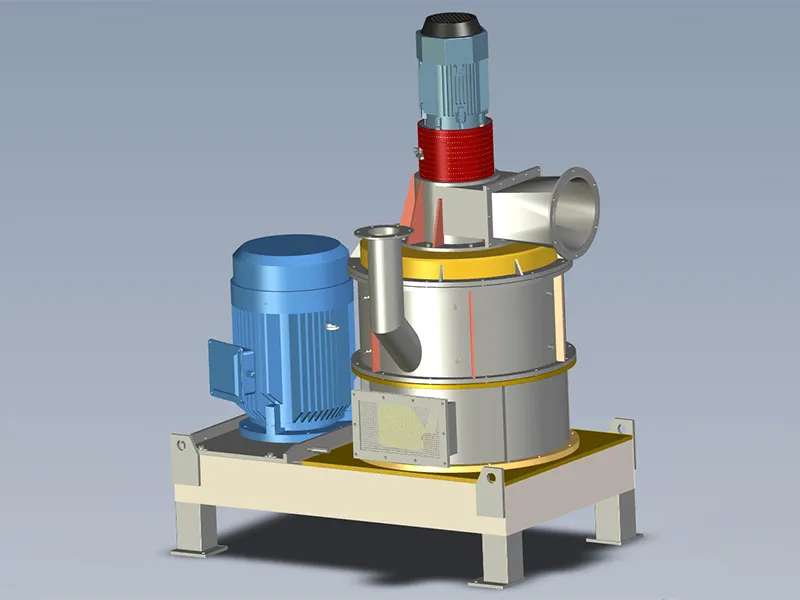

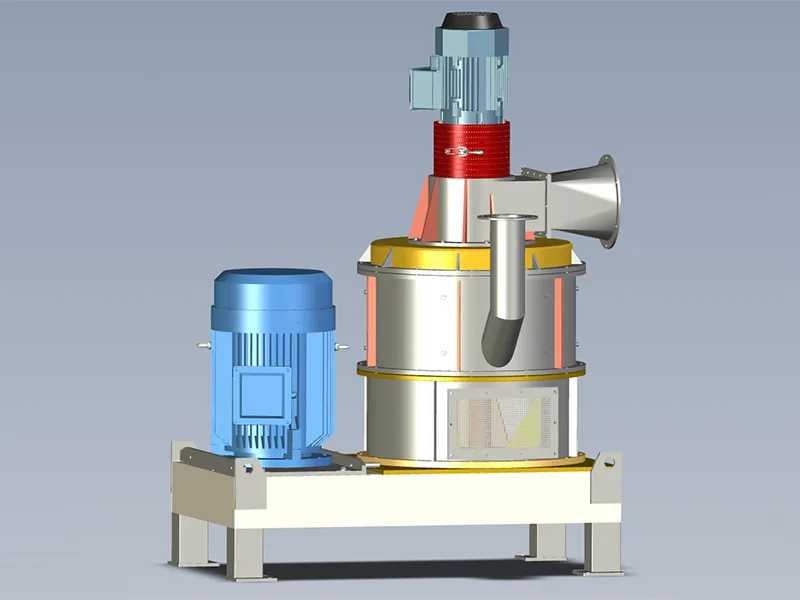

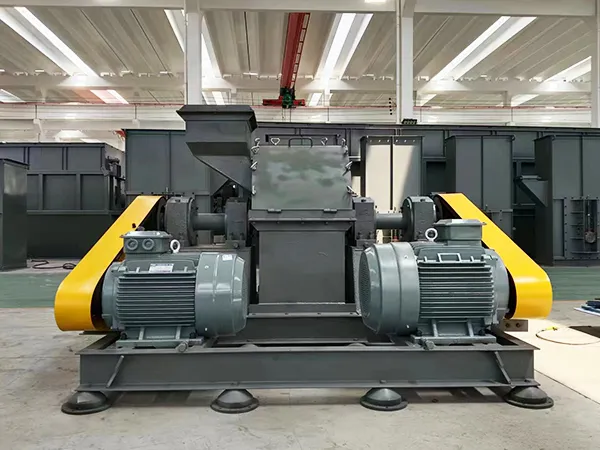

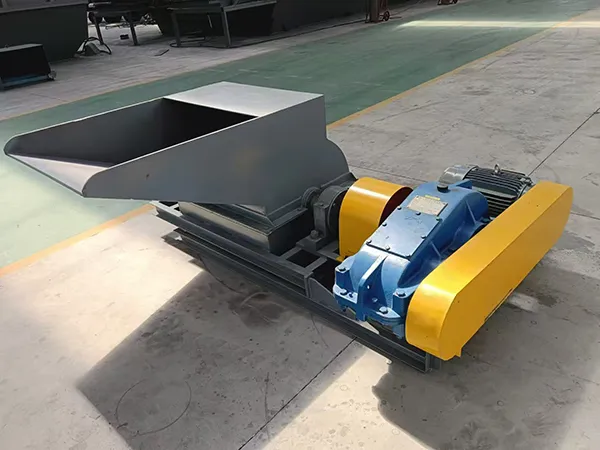

Micro Powder Grinding Mill

Particle size reduction mill for milling, grinding and micronization

Micro Powder Grinding Mill

Particle size reduction mill for milling, grinding and micronization

High-speed milling combined with precision grinding and micronization offers an efficient solution for producing fine powder products. The micro powder grinding mill integrates several systems, including feeding, grinding, classification, and an airflow system, ensuring an enhanced process from raw material input to finely milled output. With a combination of a rotating grinding plate, fixed gear teeth, and pressurized airflows, the mill repeatedly impacts, shears, and classifies the material until the desired powder consistency is achieved.

| Model | Grinding diameter (mm) | Grinding motor (kW) | Classifying motor (kW) | Air flow (m³/h) | Production capacity (t/h) |

| 600 | 30 | 5.5 | 2200 | 0.2-0.6 | |

| 700 | 35-45 | 7.5 | 2800 | 0.3-0.8 | |

| 850 | 55-75 | 11 | 4000 | 0.8-1.5 | |

| 1000 | 75-90 | 15 | 5500 | 1.0-2.0 | |

| 1100 | 110 | 18.5 | 6800 | 1.2-2.5 | |

| 1200 | 132 | 22 | 8000 | 1.5-3.0 | |

| 1400 | 160-200 | 30-37 | 11000 | 2.0-4.0 |

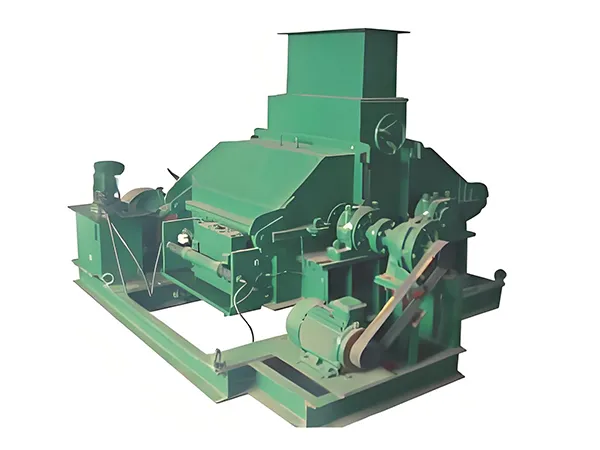

How to choose the right fertilizer production equipment for my plant?

Choosing the right equipment for your fertilizer production project starts with understanding your production needs. Here are a few key questions that help narrow down the best options:

- What type of raw materials are you working with?

- Do you aim to produce powdered or granular fertilizer? What specific characteristics should the final product have?

- What is the desired output capacity for your production line?

- What are the local environmental conditions, such as temperature and material moisture levels?

- What heat source will your drying equipment rely on?

Once we have this information, we can recommend the most suitable fertilizer processing equipment and production line for your needs.