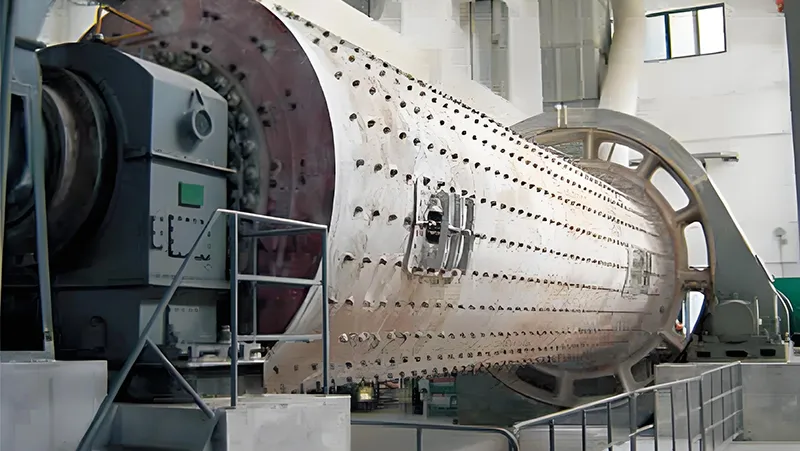

Rotary Drum Coater

Coating drum for coating granules in fertilizer production

Rotary Drum Coater

Coating drum for coating granules in fertilizer production

Rotary drum coater can improve the storage and usability of fertilizers. By applying a protective layer to granules, it effectively prevents caking and ensures a longer shelf life. Designed to function similarly to granulators, it handles the coating process efficiently to guarantee consistent and high-quality results across the production line.

Working Principle

The rotary coater is divided into two sections. In the first section, granules are sprayed with oil to create an initial coating. After passing a separating baffle, the granules move into the second section, where powder is applied to complete the coating process. This method ensures an even, thorough coating on each granule.

Specifications

| Drum size (m) | Drum | Production capacity (t/h) | Reducer | Motor | Dimensions (L×W×H) (mm) | Weight (t) | |||||

| Inner diameter (mm) | Length (mm) | Inclination (°) | Rev. (r/min) | Model | Ratio | Model | Power (kW) | ||||

| 1200 | 3500 | 2.5 | 18.07 | 5 | JZQ500 | 12.5 | Y160M-6 | 7.5 | 3500×3070×2129 | 7.0 | |

| 1400 | 4000 | 2.5 | 15.05 | 8 | JZQ500 | 20.49 | Y160M-4 | 11 | 4400×2810×2600 | 9.0 | |

| 1600 | 6000 | 2 | 12 | 10 | ZQ500 | 12.64 | Y180L-6 | 15 | 6000×3003×3216 | 11.0 | |

| 1800 | 6000 | 2.5 | 11.5 | 17 | ZQ650 | 10.35 | Y180L-6 | 15 | 6000×3375×3750 | 17.0 | |

| 2000 | 7000 | 2.5 | 10.8 | 28 | ZQ650 | 10.35 | Y225M-6 | 30 | 7000×4000×4000 | 25.0 | |

| 2200 | 7000 | 2.5 | 10.85 | 38 | ZQ650 | 12.64 | Y250M-6 | 37 | 7000×4200×4200 | 28.0 | |

| 2400 | 8000 | 2.5 | 9.59 | 45 | ZL75 | 14 | Y250M-4 | 55 | 8000×4400×4400 | 41.0 | |

| 2800 | 10000 | 2 | 8.35 | 60 | ZLY315 | 14 | Y280M-6 | 90 | 10000×4700×4700 | 60.0 | |

Features

- High precision manufacturing ensures minimal wear and exceptional concentricity, improving the coating machine's durability and operational accuracy.

- Components such as gear rings and rollers are made from high-quality cast steel, providing excellent resistance to wear and extending the coater’s lifespan.

- The optimized rotation speed and internal design guarantee a uniform application of both oil and powder, delivering consistent product quality.

FAQ

What is a fertilizer production line?

What is a fertilizer production line?

A fertilizer production line is an integrated system that combines various equipment and processes for the production of different types of fertilizers. The steps typically include raw material preparation, mixing, granulation, drying, cooling, screening, and packaging.

What are the environmental benefits of an organic fertilizer production line?

What are the environmental benefits of an organic fertilizer production line?

Organic fertilizer production offers substantial environmental advantages:

- Pollution reduction

Through microbial processes, organic materials are thoroughly decomposed, lowering the risk of soil and water contamination. - Resource recycling

Agricultural waste and livestock manure are effectively used, lessening the environmental load while promoting sustainable practices.

Related Products