Automatic Fertilizer Coating System

Fertilizer equipment for coating granular fertilizers with increased production and reduced downtime

Automatic Fertilizer Coating System

Fertilizer equipment for coating granular fertilizers with increased production and reduced downtime

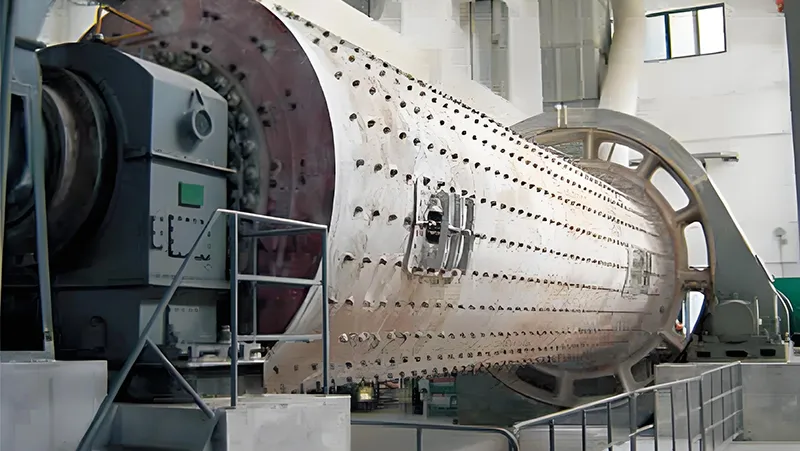

The automatic fertilizer coating system is designed to enhance production efficiency by applying anti-caking agents to fertilizers in a streamlined process. Key components of the system include a product belt weigher, a heated oil tank, a rotary drum coating machine, a screw powder applicator, and an automated control cabinet. During operation, the system continuously measures fertilizer flow, automatically adjusting the oil and powder distribution to ensure an even and precise coating. This real-time adjustment guarantees optimal protection against clumping, leading to higher-quality products with minimal production interruptions.

FAQ

What is a fertilizer production line?

What is a fertilizer production line?

A fertilizer production line is an integrated system that combines various equipment and processes for the production of different types of fertilizers. The steps typically include raw material preparation, mixing, granulation, drying, cooling, screening, and packaging.

What are the environmental benefits of an organic fertilizer production line?

What are the environmental benefits of an organic fertilizer production line?

Organic fertilizer production offers substantial environmental advantages:

- Pollution reduction

Through microbial processes, organic materials are thoroughly decomposed, lowering the risk of soil and water contamination. - Resource recycling

Agricultural waste and livestock manure are effectively used, lessening the environmental load while promoting sustainable practices.

Related Products