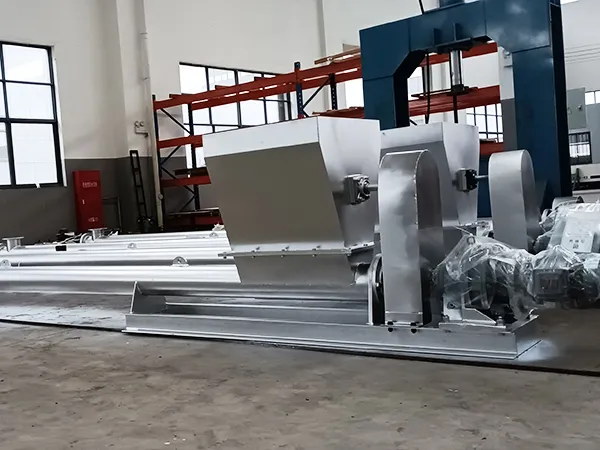

Trough Belt Conveyor

Bulk handling conveyor for transporting large volumes of bulk materials

Trough Belt Conveyor

Bulk handling conveyor for transporting large volumes of bulk materials

The trough belt conveyor, commonly known as a belt conveyor, operates based on the principle of friction-driven movement and is ideal for transporting low-abrasive bulk materials like coal, sand, grain, and fertilizers. It accommodates materials with a bulk density below 1.67 tons per cubic meter, while operating in environments between -20°C and +40°C, and handling material temperatures below 60°C. The length and design of the conveyor can be customized according to the user’s requirements, making it suitable for various industries.

Specifications

| Model | Belt width (mm) | Carrying idler type | Trough idler | ||||

| Conveying speed (m/s) | 0.6 | 0.8 | 1.0 | 1.3 | 1.6 | ||

| 500 | Conveying capacity (t/h) | 20 | 30 | 40 | 50 | 60 | |

| 650 | 40 | 55 | 70 | 85 | 110 | ||

| 800 | 65 | 85 | 110 | 140 | 180 | ||

| 1000 | 90 | 140 | 180 | 210 | 280 | ||

| 1200 | 150 | 200 | 260 | 340 | 440 | ||

| 1400 | 240 | 320 | 380 | 500 | 600 | ||

| Note: The conveying capacity will vary according to changes in the bulk density of the conveyed material, its flowability, and the angle of inclination. | |||||||

Features

- Low power consumption due to minimal relative movement between the material and the belt, resulting in reduced wear and tear, as well as higher productivity.

- Conveyor lines can be customized in length and configuration to fit various operational needs, allowing for material to be received or discharged at multiple points along the route.

FAQ

What equipment is typically included in a fertilizer production line?

What equipment is typically included in a fertilizer production line?

A complete fertilizer production line, whether for organic or compound fertilizers, usually features equipment for mixing, crushing, screening, granulation, cooling, and coating. Each machine plays a key role in ensuring efficient production and high-quality outputs.

What raw materials are commonly used in compound fertilizer production?

What raw materials are commonly used in compound fertilizer production?

To produce various types and concentrations of compound fertilizers, manufacturers commonly mix materials like urea, ammonium chloride, MAP (monoammonium phosphate), DAP (diammonium phosphate), MOP (muriate of potash), and SOP (sulfate of potash). These materials help achieve the desired nutrient balance for different crops.

Related Products