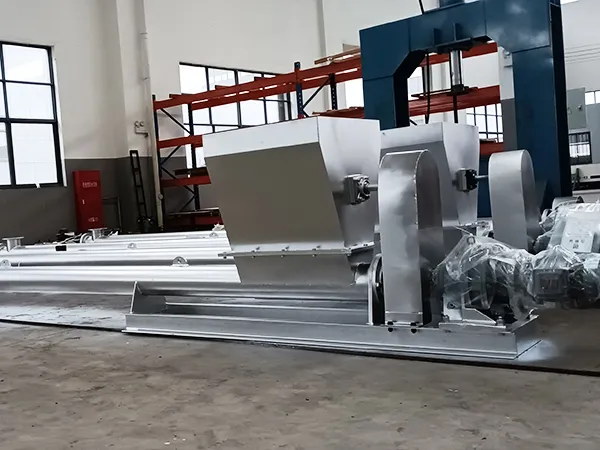

Scraper Chain Conveyor

Bulk handling conveyor for transporting bulk materials in a closed trough

Scraper Chain Conveyor

Bulk handling conveyor for transporting bulk materials in a closed trough

Scraper chain conveyors are ideal for transporting bulk materials such as powders, small granules, and small blocks within a closed, rectangular housing. These conveying machines use moving scraper chains to continuously transport materials. They can operate horizontally, at an incline, or vertically, making them versatile for different configurations. Additionally, scraper chain conveyors can function as individual machines or be combined for larger systems, providing flexibility for various industrial needs.

Specifications

| Model | Conveying speed (m/s) | Conveying capacity (m³/h) | Conveying length (m) | Motor power (kW) |

| 0.4-0.5 | 2-10 | 3-80 | 0.27-11 | |

| 0.4-0.5 | 10-15 | 3-80 | 0.4-15 | |

| 0.4-0.5 | 15-20 | 3-80 | 0.6-18.5 | |

| 0.4-0.5 | 20-30 | 3-80 | 1.5-30 | |

| 0.4-0.5 | 30-40 | 3-80 | 1.5-37 | |

| 0.4-0.5 | 40-50 | 5-80 | 2.2-55 | |

| 0.4-0.5 | 50-60 | 5-80 | 3-75 | |

| 0.4-0.5 | 60-80 | 5-80 | 7.5-75 | |

| 0.4-0.5 | 80-100 | 5-80 | 11-75 |

Features

- The conveyor system allows for multiple feed and discharge points along the transport path, enabling efficient and adaptable bulk material handling.

- Material is transported within a sealed housing, making it suitable for handling large, toxic, explosive, or high-temperature materials while improving working conditions and reducing environmental pollution.

- The conveyor supports various configurations, whether horizontal, inclined, or vertical, offering broad adaptability for different operational needs.

FAQ

What equipment is typically included in a fertilizer production line?

What equipment is typically included in a fertilizer production line?

A complete fertilizer production line, whether for organic or compound fertilizers, usually features equipment for mixing, crushing, screening, granulation, cooling, and coating. Each machine plays a key role in ensuring efficient production and high-quality outputs.

What raw materials are commonly used in compound fertilizer production?

What raw materials are commonly used in compound fertilizer production?

To produce various types and concentrations of compound fertilizers, manufacturers commonly mix materials like urea, ammonium chloride, MAP (monoammonium phosphate), DAP (diammonium phosphate), MOP (muriate of potash), and SOP (sulfate of potash). These materials help achieve the desired nutrient balance for different crops.

Related Products